-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

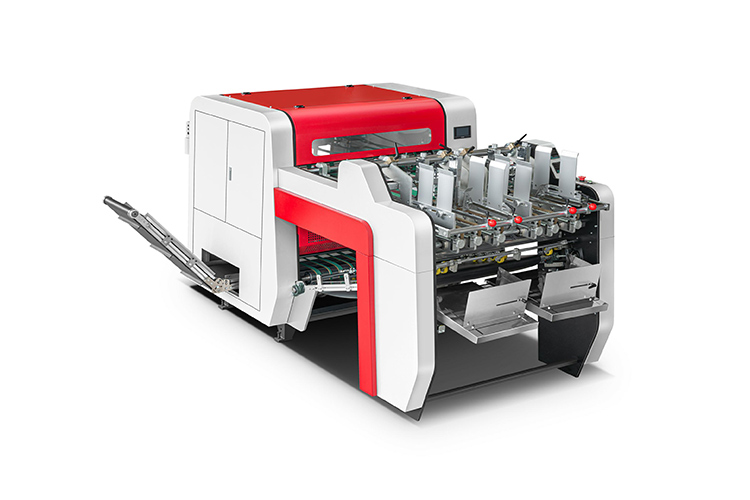

Grooving machines are essential tools in the packaging and printing industries, particularly for processing materials like cardboard, paperboard, and corrugated fiberboard. These machines create precise grooves or channels in the material, allowing for easy folding and shaping into boxes, displays, and other packaging products.

In this article, we will explore the working principles of grooving machines, with a focus on cardboard grooving machines, their key components, and their applications in modern manufacturing.

A grooving machine is a specialized piece of equipment designed to cut uniform grooves into materials such as cardboard, paper, or plastic. These grooves facilitate clean bends and folds, ensuring that packaging maintains structural integrity while remaining easy to assemble.

There are different types of grooving machines, including:

Manual grooving machines (for small-scale operations)

Automatic grooving machines(for high-speed industrial production)

The most common type used in packaging is the cardboard grooving machine, which handles corrugated and solid fiberboard efficiently.

1.Material Feeding

The process begins with feeding a flat cardboard sheet into the machine. In automated systems, a conveyor belt or suction feeder ensures smooth and consistent material entry.

2.Positioning and Alignment

The cardboard is aligned using guides or sensors to ensure accurate grooving. Modern machines use **computer numerical control (CNC)** for precision.

3.Grooving Mechanism

The actual grooving is performed using one of the following methods:

Rotary Blades: A set of rotating cutting wheels press into the cardboard at predetermined positions, creating clean, V-shaped grooves.

Crushing Wheels:Instead of cutting, some machines compress the material to form a foldable crease without fully penetrating it.

Laser Cutting (Advanced Models):A high-precision laser burns a fine groove into the material, ideal for intricate designs.

4.Depth and Width Adjustment

Operators can adjust the groove depth and width based on material thickness and folding requirements. This ensures the cardboard folds neatly without cracking.

5.Ejection and Stacking

After grooving, the cardboard sheets are ejected and stacked for further processing, such as printing, die-cutting, or box assembly.

1. Feeding System – Ensures smooth material input.

2.Cutting Unit – Contains the rotating blades or crushing wheels.

3.Control Panel – Allows operators to adjust speed, depth, and groove spacing.

4.Conveyor Belt – Moves the cardboard through the machine.

5.Waste Removal System – Clears debris from the cutting area to maintain efficiency.

Packaging Industry: Producing folding cartons, gift boxes, and shipping containers.

Display Manufacturing:Creating retail stands and promotional displays.

Bookbinding:Preparing covers and spine reinforcements.

Furniture and Interior Design:Crafting lightweight cardboard structures.

Precision:Ensures consistent groove depth for uniform folding.

Speed:Automated models process hundreds of sheets per hour.

Versatility:Works with various materials, including corrugated and solid board.

Reduced Waste:Clean cuts minimize material damage.

Grooving machines, especially cardboard grooving machines, play a crucial role in modern packaging and manufacturing. By understanding their working principles, businesses can optimize production efficiency and improve product quality.

Whether for small-scale operations or large industrial setups, investing in the right grooving machine can significantly enhance productivity and precision in packaging design.

Would you like recommendations on choosing the best grooving machine for your needs? Let us know in the comments!