-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

Saili offers a wide range of cardboard grooving machines designed to meet various business needs. Our machines are suitable for 150-350gsm cardboard and come with multiple functions and models. Saili’s machines are built to enhance productivity and efficiency while delivering excellent results.

1. Wide Range of Models: Available for 150-350gsm cardboard with various functions and models to meet diverse application needs.

2. Fully Automatic: Designed for high efficiency and seamless operation with minimal manual intervention.

3. Easy to Operate: User-friendly interface that simplifies the operation process.

4. High Precision: Achieves precision with an error margin of less than 0.1mm, ensuring accurate grooving results.

5. Versatile Applications: Suitable for a variety of applications, providing flexibility in production.

6. Top Quality Machines: Saili guarantees the best quality, including paper grooving machines, rigid box cardboard V grooving machines, automatic cardboard grooving machines, and CNC V grooving machines.

0.05mm grooving accuracy

groove type: U groove, V groove, L groove, partial groove, etc.

Automation option: dual direction grooving

29 years of production experience Industry standard setter

Intelligent design: automatic knife adjustment,edge correction and rolling belt adjustment.

Multi-functional options: corner cutting and grooving integration, slitting and corner grooving integration, etc.

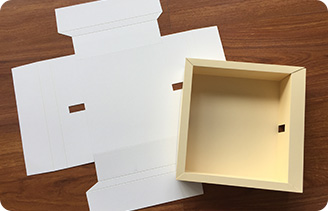

Saili grooving machine brings the v groove process can add personalised and fashionable sense of electronic products, enhance the brand image of electronic products. For example, Apple mobile phone box, through the Saili grooving machine v groove process to achieve a unique box design (open the upper and lower lids of the time difference of 6 seconds), with such a unique box design to ensure the safety of the product is opened. Apple watch band packaging, Saili grooving machine to provide a unique partial jump knife grooving process to help create anti-counterfeiting performance of the cardboard three-dimensional packaging.

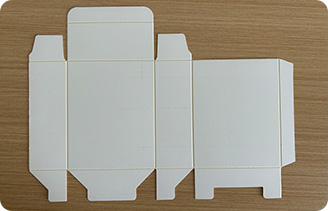

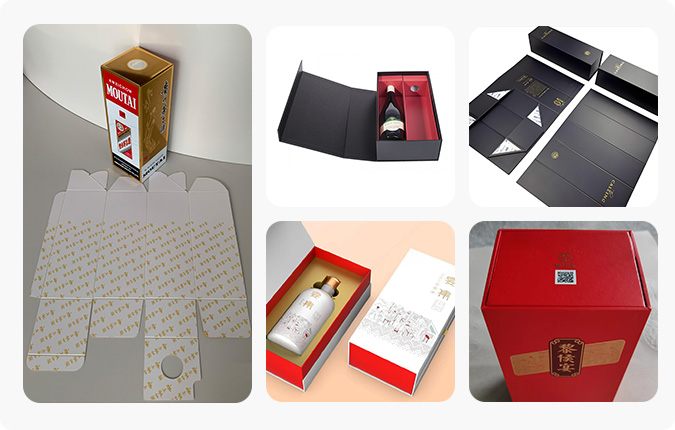

The grooving process brought by Saili grooving machine plays an important role in the design of wine packaging, through the precise V groove (or combined with L groove) process to achieve accurate folding and moulding of box, ensuring accurate packaging dimensions and upgrading the packaging, especially to increase the high-end image of wines, and to enhance the value of the brand.

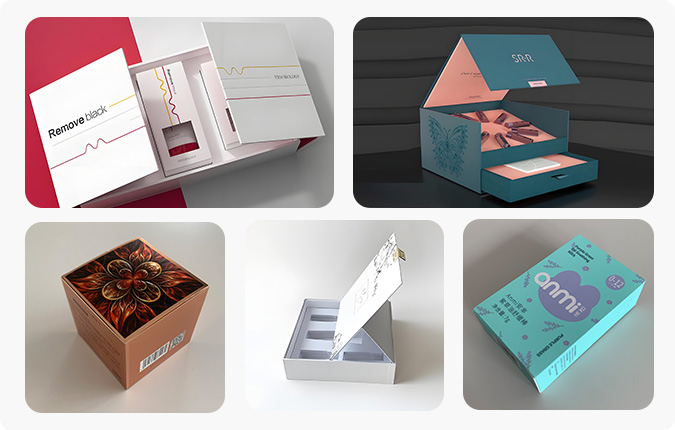

Brand bags, watches and high-grade jewellery packaging can be achieved through the grooving process of SAILI grooving machine to achieve a complex multi-layered packaging structure, enhancing its aesthetic and functionality; through the precise grooving, to ensure that the various parts of the luxury packaging box fits perfectly, to enhance the brand image;

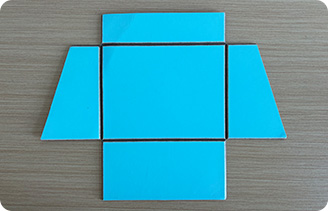

High-end chocolate needs more sophisticated packaging to attract consumers, and the grooving process can help branded chocolates upgrade their packaging. A well-known international brand of chocolate has realised a complex packaging structure design (multi-layer, multi-angle cardboard folding design) through the v groove process of Saili grooving machine.

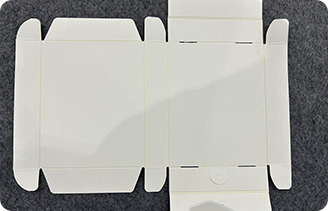

Cosmetic packaging is mainly based on folding cardboard boxes, slotted cardboard boxes are not only shaped after the angular beauty, not easy to deform, and easy to disassemble more space-saving, reduce transport costs. In recent years, a number of internationally renowned brands of cosmetic packaging boxes using Saili grooving machine, the grooving process used to the fullest.

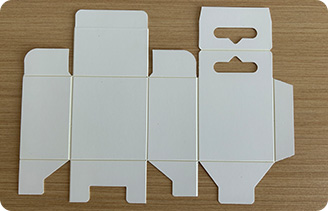

Saili invented the core technology of grooving machine (grooving is the removal of V-groove fibres from the cardboard /grayboard used in the box), and applied this technology to the manufacturing process of the box, which improves the visual effect of the box as well as the stability of its structure, making it easy to be assembled.

SAILI specialises in the production of automatic grooving machines, automatic bidirectional grooving machines, automatic corner cutting and grooving machines, CNC grooving machines and so on. According to your material type, size and functional requirements, SAILI professionals can recommend the right grooving machine according to your needs one by one.

SAILI SLZ-928S, SLQ-600S and SLQ-600C grooving machines adopt servo grooving knives ,so enjoy the advantage of automatic left and right movement of the knife, the accurate unit of movement is 0.02mm,which can be a perfect solution for you to solve the problem of knife adjustment.

SAILI SLZ-928S and SLQ-600C have this optional function, at the same time with the data memory function, you can save the current work data, the next time you run just one key operation can complete the machine parts of the automatic position, greatly save labour, improve production efficiency.

SAILI SLZ-928C is professional for partial V-grooving, adopting servo jump knife to solve the difficulty of partial V-grooving of cardboard.

Yes, you can. SAILI has automatic corner cutting and grooving machines, such as SLG-850S, SLG-600BG and SLG-600G, which come with the function of cutting the grayboard corners and help you to save the step of die-cutting separately .

Every grooving machine comes with an automatic sharpener and extra 20 blades.

Saili has been deeply plowing in the field of grooving machinery since 1996, and has created the core technology of grooving machine, providing diversified grooving solutions for different boxes processing.

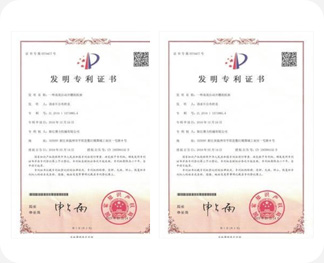

Saili owns 6 invention patents, 102 utility model patents and 5 software copyrights.

Saili has independent modernized production workshop, accessories workshop and finished machine workshop.

10,000㎡ of finished machine workshop ensures that the monthly inventory reaches 150~200 units, ensuring fast delivery.

70% of the parts on the machine are processed by ourselves, and individual machining centers process only one part all year round to better grasp the precision and quality; each part is coded and stored in an orderly manner according to the code, which is also convenient to provide better after-sales service for the customers.

Saili has cooperated with 90% of China's top 100 printing and packaging enterprises, and achieved excellent reputation.

Saili grooving machine is grateful for the love of more than 4000 customers, the machine has been sold to more than 80 countries in the world, in the future, Saili will continue to innovate, research and development, and launch more automatic, intelligent grooving machine.

Welcome to our website. If you have any requests or suggestions, please fill in and send the

following form. Please allow us to provide you with the best service.