-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

Through continuous investment in research and development, we have the first patented fully automatic cardboard bidirectional corner cutting and grooving machine in China, which has greatly improved production efficiency.

Our goal is to keep you at the forefront of your target market with our cutting-edge products.

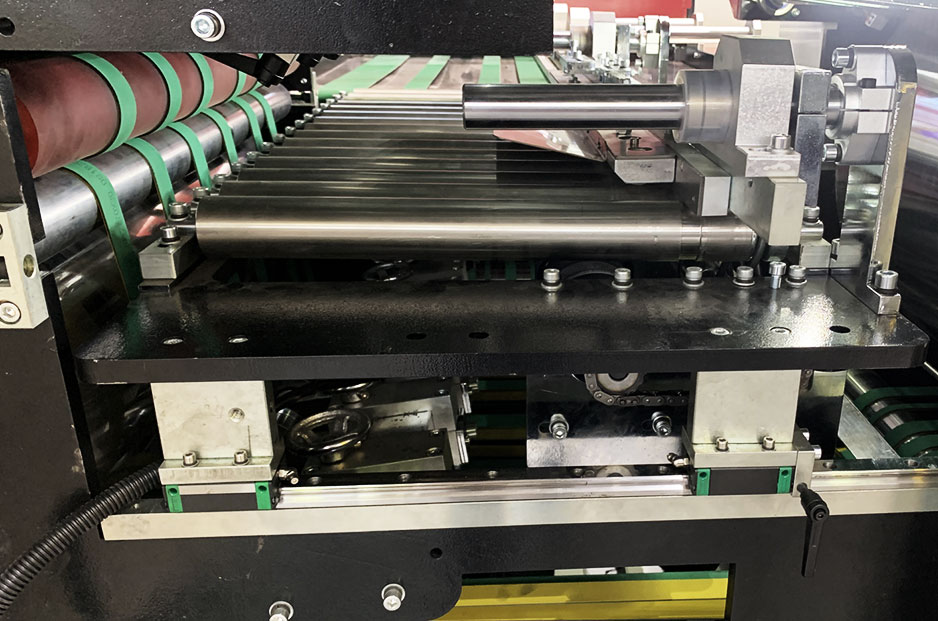

Cardboard grooving is a V-groove on the back

of the paper surface, the cardboard surface comes with a beautiful printed highlight pattern, the conventional top-down belt friction

separation conveying method will produce scratches on the surface of the cardboard , affecting the visual effectiveness of the product,

Fida feeds the top-down separation conveying, solving the frictional scratching situation in the separation process.

The cardboard is soft and thin in nature and the stability of its entry into the drum guarantees the accuracy of the cardboard grooving.

We ensure that the cardboard always enters the grooving section in a top-down manner by means of a rational drum layout, which guarantees the stability of the cardboard transport when turning.

The number of grooves in the cardboard is longitudinal and the spacing of each groove type affects each other, making it more difficult to adjust the knife. The cardboard CNC knife adjustment automatically converts the spacing of each groove type through the program, and the knife groove position is toggled by a robot to achieve intelligent knife adjustment.

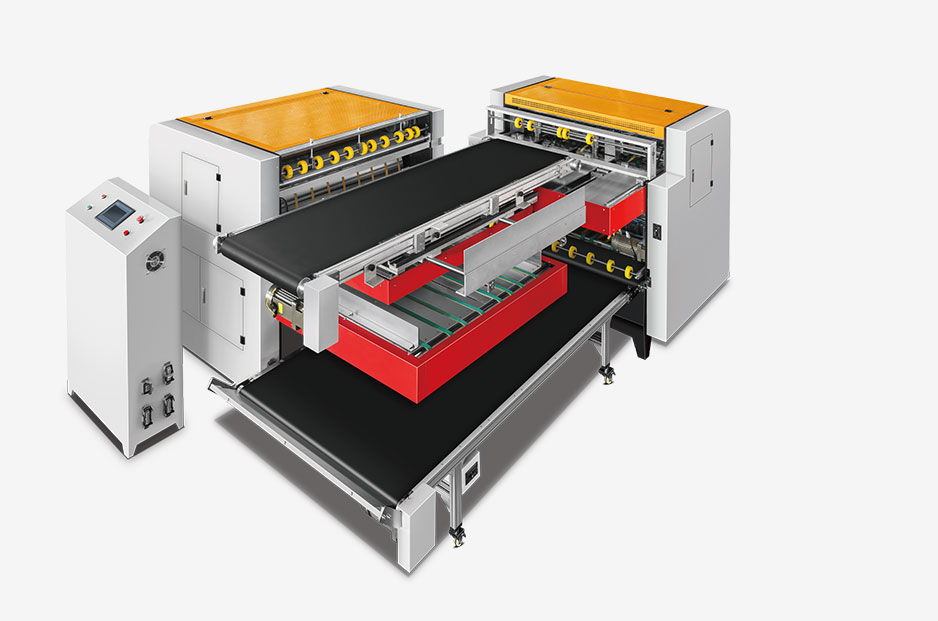

The slitting of grey board is to slit large size board into small size, we use the conveyor belt close to the big drum to position the board for conveying, and the single knife slides through the board in the conveying path to achieve slitting, which ensures the smoothness of the slitting surface and the accuracy of the board.

The existing process of cutting grey board from large to small sizes and then grooving it through a grooving machine is the existing process.

However, we have realised an integrated machine for slitting and grooving grey board by conveying the board along a large drum with additional slitting and grooving tools in the path of the drum.

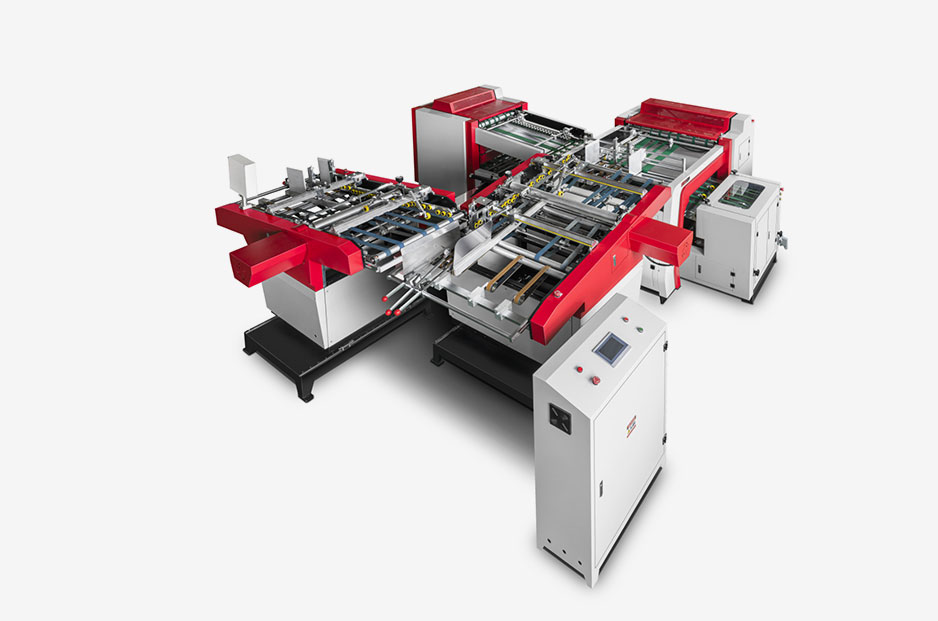

The lid & base boxes are made of a kind of grey board folded with the 4 corners removed.

The corner cutting and grooving machine is to make a partial cut line to the four corners of the grey board and to make a V-groove line in both

directions on the back of the cut line, when the V-groove line and the partial cut line intersect, the four corners will be cut off from the cardboard and the cardboard completes this function at the same time as the grooving.

Welcome to our website. If you have any requests or suggestions, please fill in and send the

following form. Please allow us to provide you with the best service.