-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

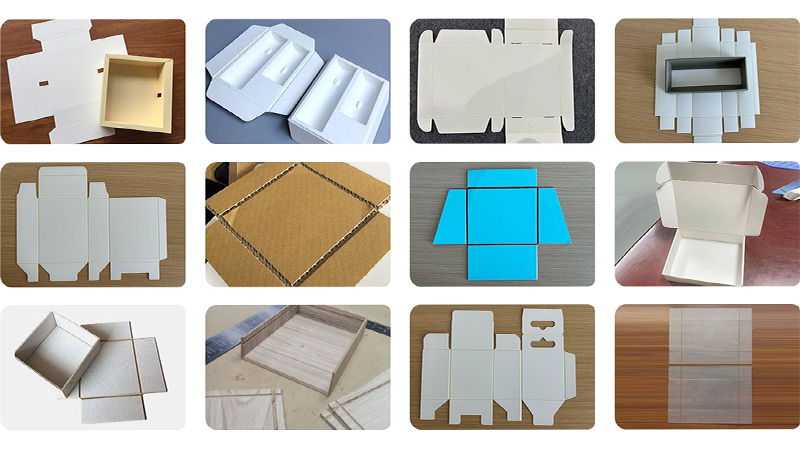

Grooving is a key technology in the packaging industry, especially when producing high-quality paperboard or greyboard cartons. By removing fibers along specific lines, grooves can form precise folds that enhance the functionality and aesthetics of a package. The process is commonly used to form V-grooves, U-grooves, and L-grooves , each of which has a different purpose in carton manufacturing.

Saili invented the core technology of grooving machine (grooving is the removal of V-groove fibres from the cardboard /grayboard used in the box), and applied this technology to the manufacturing process of the box, which improves the visual effect of the box as well as the stability of its structure, making it easy to be assembled.

Types of Grooves and Their Functions

V-grooves are V-shaped indentations cut into the material that allow for clean, sharp folds. This groove type is widely used in packaging because it offers the following benefits:

Improves structural stability by ensuring precise fold angles.

Enhances visual appeal with crisp, professional edges.

Simplifies assemblyby guiding the folding process.

U-grooves have a rounded, U-shaped cut, ideal for thicker materials that require a deeper indentation. Benefits include:

Reduces the risk of cracking in dense paperboard.

Enables rounded or curved designs to fold more smoothly.

Provides better durability in high-stress folding areas.

L-shaped groove creates right-angle folds and is often used in special packaging designs. Benefits include:

Precise 90-degree bend , suitable for rigid box structures.

Suitable for complex packaging with multiple folding points.

Increased stacking strength due to edge reinforcement.

Improved aesthetics: Grooved edges give packaging a sophisticated, high-end look.

Structural integrity: Ensures that the carton retains its shape and lasts.

Easy to assemble:Simplifies the folding process and reduces production time.

Customization:Different groove types allow for unique design flexibility.

Grooving is an essential process in modern packaging, offering both functional and visual advantages. Whether using V-grooves, U-grooves, or L-grooves, manufacturers can enhance the quality, durability, and assembly efficiency of their products. By integrating grooving technology, brands can deliver premium packaging solutions that stand out in the market