-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

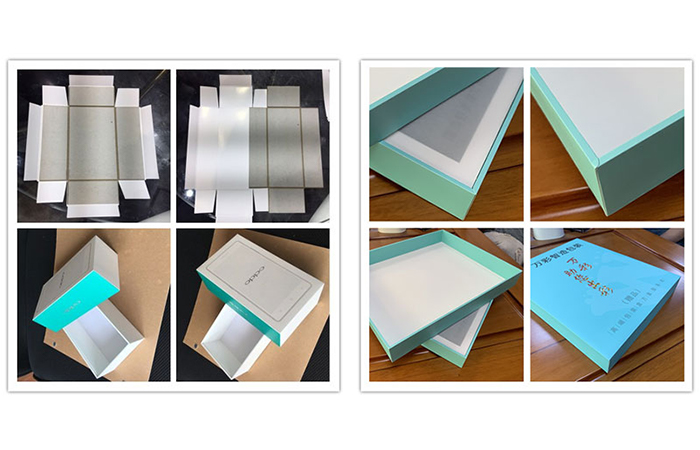

Greyboard grooving has three core elements: position, depth, and width.

1. The position should follow the box structure, and the slotting line must be precisely aligned with the indentation line (or crease line) on the box's design layout. (Any slight offset will result in cardboard tearing or folding corners not being straight when folding.)

Angle Matching: Depending on the type of box (e.g., tip & base box, book box, drawer box, etc.), the slotting angle is usually 45° to ensure that the two neighbouring edges will fit tightly together when folded to form a perfect 90° right angle. Other angles may be used for some special designs.

2. Depth: This is the most critical rule, which directly determines success or failure.

Golden Rule: The groove depth should normally be 1/2 to 2/3 of the material's total thickness.

Too shallow: It will make the cardboard difficult to fold, the fold will burst (the paper fibre will break), the appearance will be damaged, and it will not even be possible to shape.

Too deep: the support strength of the cardboard is greatly weakened, resulting in a loose box structure with easily deformed sides, or even breakage during the production process.

3. Width rule: ensure smooth folding

The principle of moderation: The width of slots needs to provide enough space for material compression and movement during folding.

V-grooves are the most common type of groove. Its width is proportional to its depth. A moderate width ensures tight inside corners and a clean appearance when folded.