-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

In the packaging and printing industry, precision and efficiency are essential to produce high-quality rigid cartons, luxury packaging and display materials. V-grooving is a specialized technology that creates precise bevel grooves on materials such as paperboard, greyboard and other rigid substrates, allowing for clean folding and professional finishing. With the advancement of automation technology, automatic bidirectional groovers and automatic groovers have revolutionized production methods, providing unparalleled precision and speed.

This article explores the main applications of V-grooving and how automatic groovers can enhance the manufacturing process.

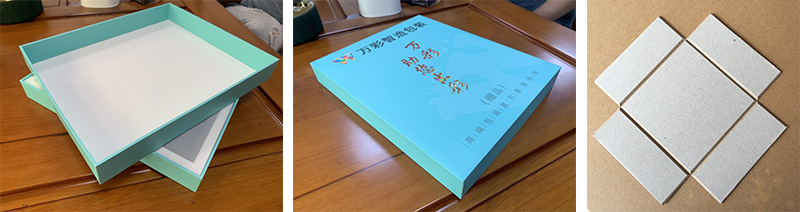

Luxury packaging such as high-end gift boxes, electronic product housings and cosmetic packaging requires clear and sharp creases to create a premium look. V-grooving ensures precise creases without damaging the surface, making it ideal for:

Hardcover book boxes

Jewelry and watch boxes

Perfume and cosmetic packaging

Retail displays, shelf packaging and promotional displays often use thick cardboard or corrugated cardboard. V-grooving allows for easy assembly while maintaining structural integrity.

Heavy packaging for electronic products, mechanical equipment and medical devices requires durable and foldable materials. V-grooving ensures sharp creases without weakening the structural strength.

Why choose Sailiautomatic groover?

As a professional groover manufacturer and supplier, the company has developed a variety of automated groovers after years of technical development and improvement, which is time-consuming and less accurate than the traditional manual groover method. Modern automatic two-way groovers and automatic groover have significant advantages:

The digital control system ensures ±0.15 mm accuracy, eliminating human error.

The groove depth and angle are consistent for all workpieces.

Automated feeding and cutting reduces labor costs.

Dual-direction slotting processes two edges simultaneously, doubling efficiency.

Processes a wide range of material thicknesses (from thin cardboard to hard greyboard).

Adjustable blade settings to accommodate different slot depths and angles.

Automatic scrap removal system prevents jams.

Precision cutting minimizes material waste.

V-grooving is an essential process for industries that require high-quality, foldable packaging and displays. With automatic slotting machines, manufacturers can achieve faster production speeds, higher precision processing, and reduce operating costs. Whether it's high-end rigid boxes, retail display boxes, or industrial packaging, automated V-grooving technology ensures perfect results every time.