-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

Feature:

V-grooving and partial grooving for all kinds of cardboard, grey board, corrugated board and etc .

It has high grooving accuracy, dustless, little noise, highly effective, energy conservation, environmental protection. Help you to solve the package grooving problem.

Advantages:

1. Servo adjusts the depth size of the grooving knife, the minimum precision of knife movement is 0.01mm.

2.Servo control the inward and outward movement of the grooving knife to realise the partial grooving function.

3. Magnetic grating controls the left and right movement of the grooving knife, the minimum precision unit is 0.01mm.

4.Automatic edge correction: rubber wear-resistant guiding wheel is adopted to ensure the stability of guiding, which greatly improves the precision of grooving, easy to operate and safe to use.

5. Automatic feeding and collecting; automatically transfer the waste material to the outside of the machine, solving the problem of manual clearing of waste and greatly improving the output.

Feeding section: with vacuum adsorption for favourable sheet feeding.

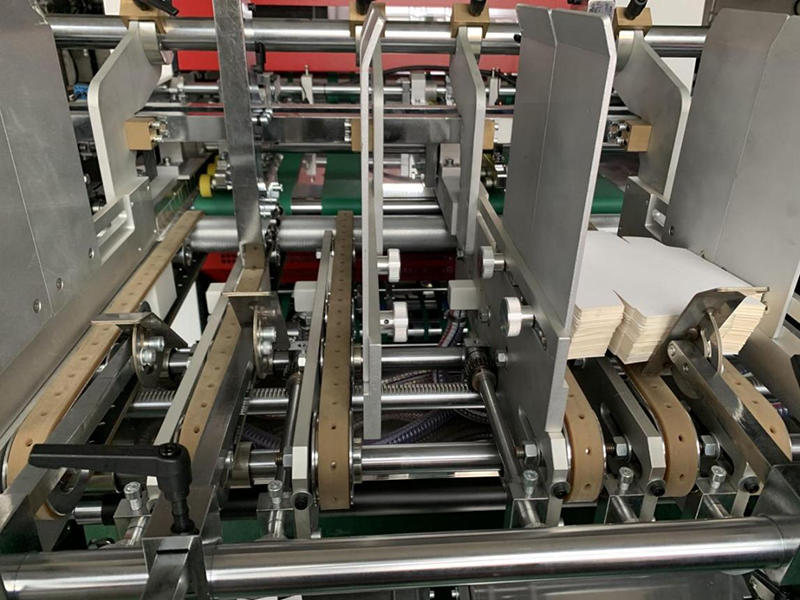

SLZ-928C automatic partial grooving machine Partial grooving is a modern, up-to-date grooving process that allows slotting anywhere on the cardboard and greyboard. This machine can groove straight or partial grooves with advanced servo knife.

SAILI's exclusive first patented grooving machine.

1.Width :120-850mm ,length 120-550mm

2.Thickness : 200GSM -3.5mm ,thin cardboard ,greyboard

3.Digital grooving knives + servo knives

4.Vacuum feeding belts ensure smooth feeding of all types of paper.

5.Side Independent Waste Discharge

View More